Project Name: NnG (Neart na Gaoithe) Offshore Windfarm

Developer: EDF Renewables UK & ESB 50/50 joint venture

Date: August 2022 – Ongoing

Client: GE/HSM/MGH

Location: Scotland, Fife Coast

Scope of work: Access Solutions, Loler Inspectors

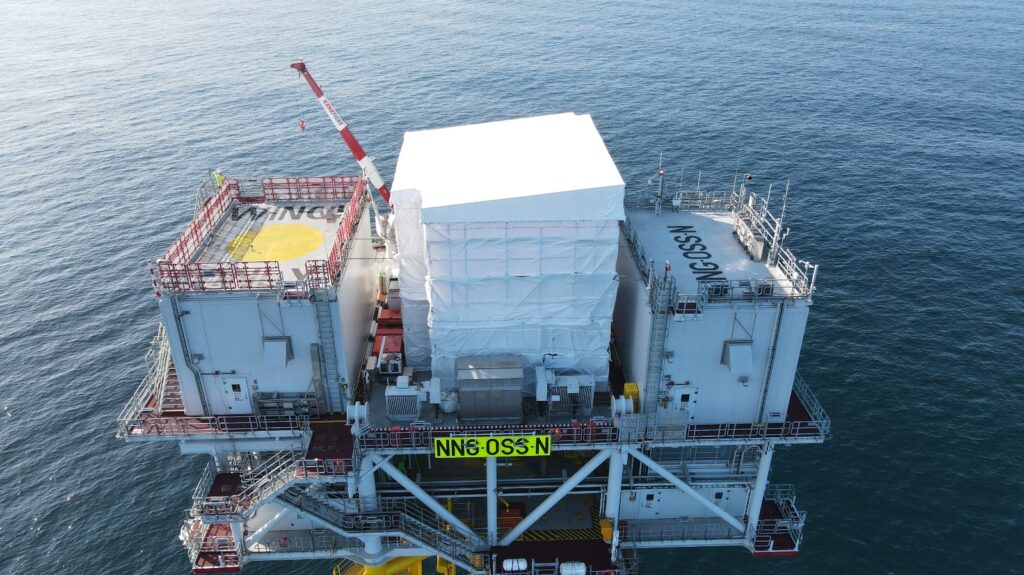

The NNG Offshore Windfarm is a joint venture between EDF Renewables UK & ESB, two leading developers in the renewable energy sector. The project aims to produce up to 450 MW of low carbon energy and will have a maximum of 54 turbines. NnG will provide power for around 375,000 homes.

BGB were enlisted to provide access solutions in a variety of situations to assist with the construction phase. Our works included but were not limited to slung scaffolds for painting works below the substation. Several independent scaffolds for E & I installation works. Birdcage scaffolds for cable pulling and routing. Providing a scaffold for the installation of a TX which included split level boarded platform for cable installation, loading bay, lifting beams and equipment, weather proofing encapsulation to enable works to continue in difficult weather conditions.

Access Solutions:

- Slung scaffolds for painting work below the substation.

- Independent scaffolds for E & I (Electrical and Instrumentation) installation works.

- Birdcage scaffolds for cable pulling and routing.

Specific Installations:

- Scaffold for the installation of a TX (Transformer).

- Split level boarded platform for cable installation.

- Loading bay for equipment.

- Lifting beams and equipment for installation purposes.

- Weatherproofing encapsulation to enable work to continue in difficult weather conditions.

Key Activities:

- Painting works below the substation.

- Electrical and Instrumentation (E & I) installation works.

- Cable pulling and routing.

- Installation of a Transformer (TX) with specific requirements such as split-level boarded platform, loading bay, lifting beams, and weatherproofing.

It was important to maintain communication and coordination with the clients (GE/HSM/MGH) and ensure that all safety and regulatory standards were met during our package of works.